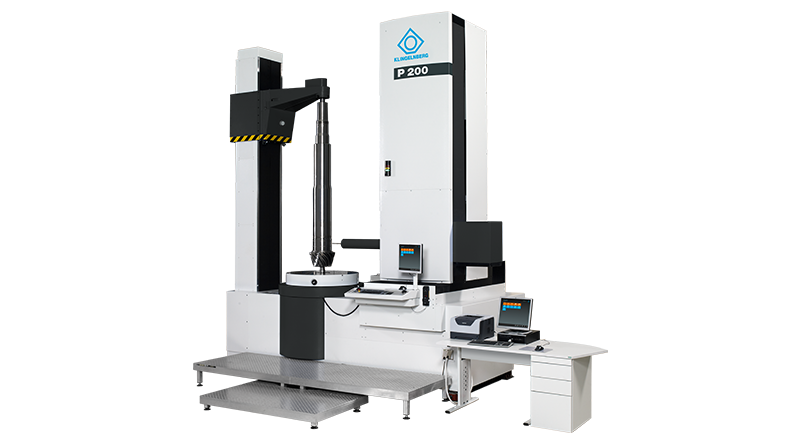

Highlight

KLINGELNBERG Precision Measuring Center P 200

Fast and accurate measured value logging in connection with a high-precision workpiece rotary table

- Extremely smooth-running rotary table axis in form-measurement quality

- Rotary table load up to 20,000 kg with high load reserves for impacts during workpiece loading

- Rotary table drive via AC torque motor (direct drive)

- Table plate (1,000 mm diameter) with switchable air bearing for pre-alignment of heavy workpieces

- Uniform, constant rotary transmission even at extremely slow motion

- Acceleration control of the rotational axis using various ramps

- Directly coupled angle measuring system with high absolute accuracy