KLINGELNBERG Drive Technology/Customized Bevel Gears

KLINGELNBERG Drive Technology/Customized Bevel Gears

Technological service provider right up to the last detail

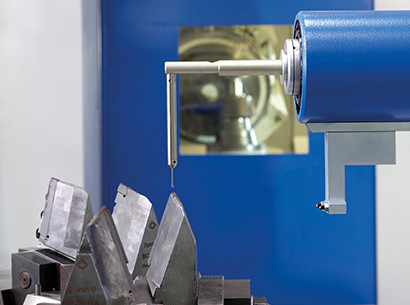

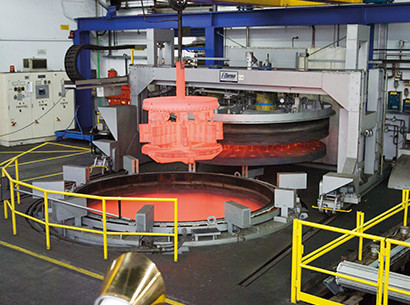

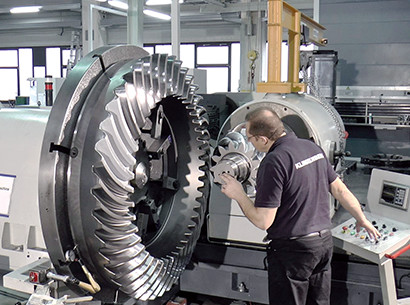

In the bevel gear product sector, Klingelnberg develops and produces a wide range of gear components and is the global market leader in the production of large spiral bevel gears. From standard solutions to high-tech applications – for the aerospace industry and Formula 1, for example – Klingelnberg offers its customers tailor-made gearing solutions. Beside production-related activities, the range of services also includes engineering services such as bearing-pattern optimization, calculations, design and simulation of gear components, and determination of static and dynamic factors of the complete system.

System components for the toughest applications: bevel gear sets from Klingelnberg Germany

In 1923, Klingelnberg was the first company in the world to begin made-to-order production of bevel gears using the continuous hobbing method at its site in Hueckeswagen, Germany.

A high level of innovation and close partnership with customers and suppliers have constituted a tried-and-tested success model ever since. In 2008, the Drive Technology Germany division was moved from the original plant in the center of Hueckeswagen to the Winterhagen West 2 industrial zone, located approximately five kilometers away. Today, spiral bevel gears with diameters up to 3,000 millimeters are manufactured there – using state-of-the art methods.